Stone Wastewater Treatment Systems

Achieving 1-2 micron water that can be safely reused throughout the shop

Ask us about our dual press systems for larger facilities

Zero discharge reuse systems for stone fabricators

Utilize Beckart’s Hypack filter presses to achieve 1-2 micron water for reuse

Filter press manufactured in-house with over 2,000 filter press installations worldwide

Velcro style filter cloths allow for excellent cake release and can be changed out in just a few minutes

UL/CSA listed controls panel built in house

Touch screen HMI with custom programming

Field service and technical support

Engineers on staff (chemical, electrical, mechanical)

Parts in stock

Give us a call to discuss your needs or to trouble shoot a competitors system. We also carry a complete line of anionic polymers and cationic polymers for stone settling systems.

Reconditioned filter presses

We take in old filter presses (all makes) in on trade or outright purchase. We then sand blast, clean and paint the frame to restore the filter press to a “like new” condition. We upgrade the hydraulic components, replace the cylinder if needed and install new filter cloths on the filter plates. A rebuilt press typically costs about 60% of new.

Upgrades

If you have an existing system that does not provide the flow or the water quality you need, reach out to us for a consultation and we will make suggestions to restore or upgrade your water recycling system to meet your current needs.

Contact Us To Discuss

Stone Wastewater Treatment Systems

Save Money by Treating and

Recycling Your Wastewater In-House

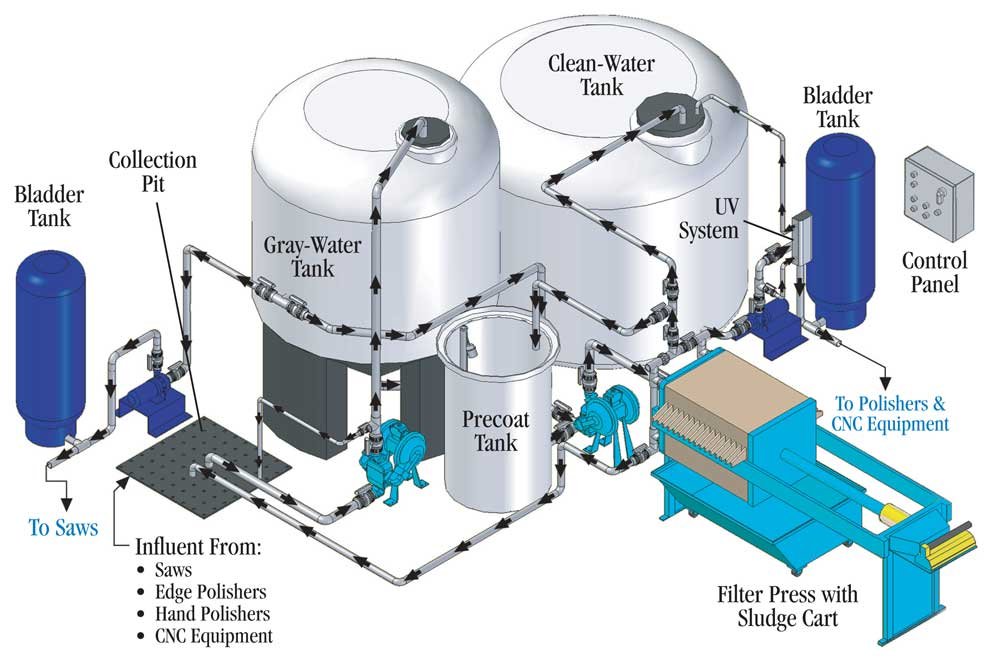

Are you wondering what the best method is for avoiding costly fees related to discharging stone wastewater into a public sewage system? The answer is to not discharge the water at all. With one of Beckart Environmental’s zero-discharge wastewater treatment systems, you can collect, clean, and reuse all of the wastewater your stone fabrication processes produce.

Your new stone wastewater treatment system will include all of the components needed to effectively separate the solid waste

in your wastewater from the water that you can reuse.

One crucial element of our stone wastewater treatment systems is our innovative Hy-Pack® filter press, which provide an effective means of dewatering sludge. Waste goes into the equipment as liquid sludge and then can be removed as dry, compacted filter cake that meets all landfill requirements, making disposal far easier than it would otherwise be. Due to decreased water costs and

non-compliance fees, many of our customers that adopt these stone wastewater treatment systems report saving thousands of dollars every month.

Contact Beckart Environmental today to determine how you can benefit from having one of our

zero-discharge wastewater recycling systems installed.

Click the thumbnail above to bring up a size comparison chart in a new window

(49 KB)

Click the thumbnail to bring up

a process flow diagram in a new window (63 KB)

Contact us to receive a PowerPoint® presentation on this system.

Hy-Pack® Filter Presses are available in five sizes to suit your needs. Your Beckart sales engineer will work with you to determine the best size to meet your current and future requirements.